HUBTEX connectivity solutions

Maximum transparency for your vehicle and fleet management

max. transparency for machine and fleet data

max. transparency for machine and fleet data Reduced maintenance costs

Reduced maintenance costs Optimised fleet management

Optimised fleet management

Instant access to live data on your forklift fleet – anytime, anywhere. Previously only possible for remote maintenance of HUBTEX forklifts, a comprehensive fleet management solution is now available. The new connectivity solutions provide you with a central overview of all vehicle and fleet data, enable you to control access and track violent damage. These optional features are available for all HUBTEX models and ensure greater transparency, security and efficiency in your operations.

Smart fleet management

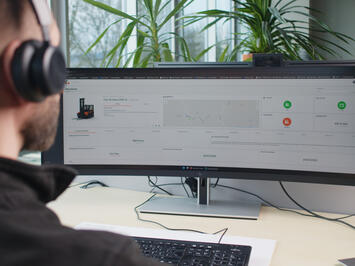

The machine connectivity is realised by a CAN-based telematics gateway that connects the industrial truck to the cloud via a 4G mobile connection. This cloud is accessed using a web-based data platform. This cloud-based data management system provides you with comprehensive machine data and enables detailed analyses of machine usage, maintenance planning, fault and battery management.

Optional extensions are also available, including remote access to Hubtex vehicles, battery level control and a daily vehicle check. These features in particular allow you to benefit from the in-depth integration of the solution into your Hubtex vehicles. Take advantage of the efficiency benefits. Data is transferred securely over the mobile network, while maintaining the highest data protection standards at all times.

Connectivity solutions for efficient fleet management

Curious to find out how you can make your fleet management even more efficient? Our product experts will be happy to advise you.

Basic package

Hubtex fleet management via the online portal

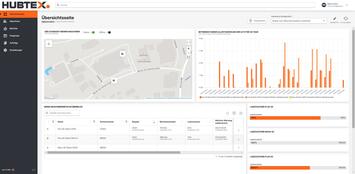

With our machine connectivity and the portal, we offer machine owners a comprehensive fleet management solution with in-depth machine integration. The system provides all relevant performance data and delivers a detailed overview of the vehicle's use. It also enables the timely recording of accidental damage and provides a transparent insight into vehicle and fleet performance data.

These functions enable us to optimise the efficiency of the vehicle fleet and ensure better planning and cost control.

The vehicle status provides a clear display of the most important information, including battery charge level, operating hours, vehicle messages, upcoming maintenance and the next safety inspection, so that you can keep an eye on the condition of your vehicle at all times.

This gives you detailed insights into the traceability of operating times and the use of the vehicle in operation. If the optional driver assignment is activated, you can also record how long a driver has been logged on to the vehicle.

Prevention of damage and loss of performance due to incorrect charging or maintenance.

Forklift collisions can cause considerable costs - whether through damage to people, vehicles or infrastructure. In addition, every accident leads to a loss of productivity.

To promote safe driving and reduce both the frequency and cost of accidents, vehicle collisions are recorded using a crash sensor and categorized according to severity.

The reports on vehicle and fleet performance data can be individually adapted to your needs. In addition, ready-made reports are available for efficient evaluation of this data.

Shocks

The shock values allow you to track exactly when and which driver has caused shocks to the vehicle. In combination with GPS position and the optional driver identification, important conclusions can be drawn in the event of damage.

Operating hours forecast

Based on real usage data, the system calculates the expected operating hours of the fleet. You can choose whether the hours should be forecast for a specific point in time or whether a defined number of operating hours should be calculated.

Availability

The diagram visualizes whether vehicles are in use, parked or undergoing maintenance. The bars show the remaining operational capacity of individual vehicles and the entire fleet at a glance.

The most important error codes of the vehicle are displayed for better communication with the service department.

The portal shows in the overview all upcoming service and safety check appointments and enables proactive maintenance planning. This allows assignments to be coordinated efficiently, downtimes to be scheduled in a targeted manner and maintenance to be bundled within the fleet.

The GPS function enables precise location tracking and provides a theft warning as soon as the vehicle leaves the defined area of use. In addition, the last route driven can be tracked and the use of rental vehicles can be viewed.

Via the CAN-based telematics gateway, we can remotely import parameter sets and change driver codes or reset maintenance intervals. However, the connection is not made in real time. This tool is not suitable for vehicle commissioning during construction (see remote maintenance, full).

You can set automatic notifications for selected topics.

Access to the portal via app

Optional Features

Hubtex vehicles can be activated keylessly by entering a PIN in the HIT terminal. Driver-specific codes enable precise assignment and can be integrated into the portal. Our service team creates these codes remotely and transfers them to the system.

Depending on the data protection guidelines, anonymized or personalized assignment is possible. The driver history is documented accordingly.

The sensor for built-in and exchangeable batteries monitors the electrolyte level of the battery. If the level is too low, a warning message appears on the HIT3 vehicle display for the currently installed battery, while the message is simultaneously recorded in the portal.

*available soon

The event triggers are individually customizable and enable targeted measures, such as activation of creep speed, blocking of the vehicle, requirement of a checklist to be completed.

*available soon

When the vehicle is started for the first time during the day, the vehicle display indicates the daily access control in accordance with DGUV 208-004. The execution is confirmed in the vehicle display (from HIT4) and the corresponding driver (if readable), time stamp is shown in the portal. In the event of an error, the driver can enter a short text message.

*available soon

Hubtex equips the forklift truck with a transponder reader for this purpose. The vehicle starts using the authorized employee's personal transponder, whereby the company's own RFID transponders are usually used. This eliminates key chaos and enables the tracking of driver usage data if required.

*available soon

Minimize downtime and on-site visits

with our remote management system

Remote access, full

A near real-time data connection in 1st and 2nd level support is essential for the commissioning, servicing and remote maintenance of complex vehicles such as AGVs, order picking and special vehicles. The aim is to reduce on-site operations through targeted remote access and to minimize downtimes through detailed remote diagnostics and optimized service preparation. The solution also enables remote parameterization and the resetting of maintenance intervals directly on the vehicle.

We therefore recommend adding a remote management system to our telematics solution. Integration via WLAN ensures a stable connection, enables direct access to the vehicle control system and the integration of additional control units. Encrypted connections are provided as standard; physical protection can be added as an option, for example by using key switches to deactivate remote access to the vehicle.

Connectivity solutions from HUBTEX

Answers to frequently asked questions

Is it possible to retrofit HUBTEX connectivity solutions?

Hubtex connectivity solutions can be retrofitted to a large number of existing HUBTEX trucks as standard. Simply contact the service department to check. We will provide you with a customized offer. The advanced optional functions are only available in the latest generation of control units.

Get a quote for retrofitting here.

Can the user interface and reports of the connectivity solutions be customized?

Additional training

The HUBTEX Data Portal offers flexible customization options for the user interface and the creation of tailored reports. To get the most out of it, we provide web-based training from a HUBTEX expert or the joint creation of individual reports.

How are firmware updates for fleet management carried out?

Firmware updates

This feature also enables targeted firmware updates. We recommend having this done exclusively as part of a service appointment and with a service technician on site to ensure a full functional test of the machine afterwards.